HOW Blockchain & AI USE IN MANUFACTURING?

A variety of sectors are now getting transformed thanks to the Blockchain technology. Be it retail, manufacturing, information technology, fishing, or healthcare, almost all industries are getting benefited from the Blockchain technology. On the other hand, Artificial Intelligence too have garnered the world’s attention by automating a lot of complex tasks.

It appears that the manufacturing industry is one of the most potential industries for applying and incorporating Blockchain. You can even divide manufacturing in smaller processes and all those processes or chucks will show the potential to be enhanced by Blockchain. Procurement, supply chain, inbound and outbound processes, the technology can transform them completely.

It is well known that the supply chain is the foundation of every manufacturing Blockchain. And the efficiency of the supply chain can easily be enhanced with the power of Blockchain. It will not only become cheaper but also of more advanced tracking features as well. With the intervention of this technology, the product quality will suddenly improve in the manufacturing industry.

The Blockchain contains several fronts that we can connect with the manufacturing industry and see how each front will benefit it. Data and information’s timely delivery is a core part of manufacturing. Blockchain immutability helps industries keep the data as it is. Because it is impossible to alter any info once it is in the DLT.

Tracing, transparency, and decentralization of data are also the unique benefits the manufacturing industry may get from the Blockchain technology. Data distributed over a Blockchain network comes with great security, transparency, and traceability. In the Blockchain, data is saved in multiple locations in the form of blocks to eliminate the risk of modifications.

Like all its applications, Artificial Intelligence is making its way through the manufacturing industry as well. Many artificial intelligence-based CAD tools have been developed to design new parts. These tools have capabilities to perform finite element analysis. Engineers simply input the geometries, costs, and materials and AI will generate the optimal design.

Moving forward, the manufacturing sector can create accurate models by employing artificial intelligence-powered CAD tools. After providing the system theoretical and real-world data, the software can even build digital twins. That way, engineers can view parts or the whole system digitally, without creating them in real life.

Without any doubt, the Blockchain technology can be a game-changer for the supply chain system. It can refine the system and improve it by providing more data security, better data management, and transparency. Artificial Intelligence is also a good add on here which can automate a number of redundant tasks.

Popular Blogs

-

- How Secure Is Blockchain Technology Jul 7, 2021

-

- Zero investment business in India Jun 25, 2021

-

- How Will Blockchain Technology Change The World Apr 19, 2021

-

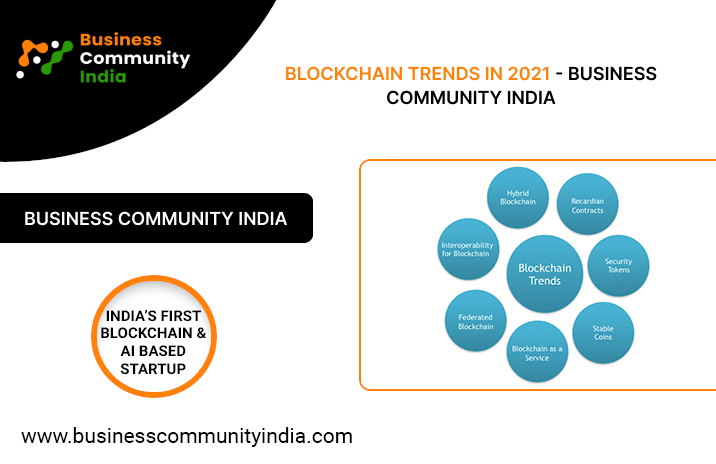

- Blockchain Trends in 2021 - Business Community India Feb 12, 2021

-

- Business Community India The Growth Partnership Feb 4, 2021

-

- Partnership With Business Community India Nov 30, 2020